About F-WHEEL

F-WHEEL Group was founded in 2013 and has dedicated a decade to research, design, and production in the E-BIKE field.

With a dual-drive approach involving a German design team and a Chinese supply chain, the company focuses on meeting the commuting needs of European and American customers.

We have developed multiple E-bike product lines, including foldable, urban, mountain, and fat-tire E-bikes. F-WHEEL holds over a hundred global patents and is an industry leader in custom development, with cumulative sales exceeding one million units.

FWHEEL EBIKE

F-WHEEL benefits from global supply chain advantages and achieves an annual production capacity of one million units. Our stable quality and cost-effectiveness make them a long-term premium supplier to retailers like Costco, Sam’s Club, Best Buy, etc.

100+ Gloabal Patents

F-WHEEL boasts a strong R&D team and actively cultivates high-value patents during the research and development process. We have obtained over 100 global patents.

Innovative R&D Team

We boast an experienced research and development team that continuously invests in innovative design and technological advancements.

Efficient Production

Advanced production equipment and automated processes ensure rapid response to market demands, reducing delivery times.

Continuous Innovation

Constantly researching and introducing new technologies to lead the development trends in the electric bicycle industry, maintaining a leading market position.

Robust Supply Chain

Establishing a stable and efficient supply chain system to ensure ample raw material supply and smooth production operations.

Our Factory

In addition to our Huizhou factory in China, we also have production bases in Zhengzhou, China, the Czech Republic, and Cambodia. These widely distributed production facilities enable us to better serve global customers, meet the demands of different markets, and ensure the stability and efficiency of our supply chain.

Our vast factory area and strong production capacity ensure that we can handle orders of all sizes. A professional R&D team and a rich portfolio of patents guarantee that our products remain at the forefront of the industry. The distribution of our production bases in multiple locations shortens delivery times, reduces logistics costs, and enhances customer satisfaction. Our strict quality control system ensures excellence at every stage, from raw material procurement to manufacturing processes.

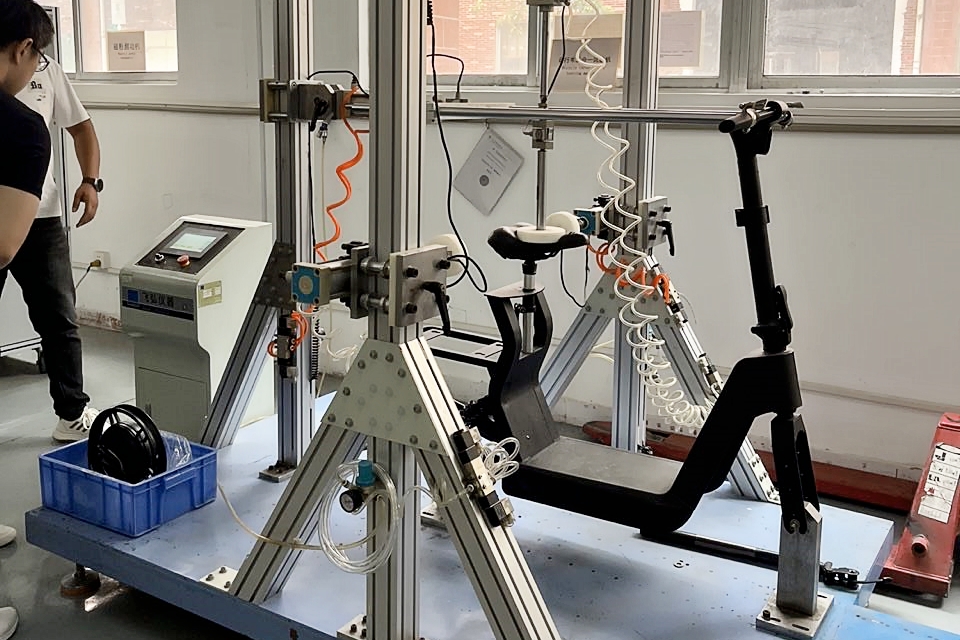

Product Testing Center

Since its establishment, F-WHEEL Factory has always adhered to the philosophy of “Quality First, Innovation Driven,” continuously striving for excellence in development. With the rising market demand, product quality has taken a crucial position in the company’s strategy. To further enhance product quality, increase customer satisfaction, and promote technological innovation, F-WHEEL Factory has established an advanced Product Testing Center. The center aims to ensure that every product meets the highest standards before leaving the factory through systematic and comprehensive testing processes, catering to the diverse needs of customers.

Overview of the Testing Center

F-WHEEL Group was founded in 2013 and has dedicated a decade to research, design, and production in the E-BIKE field. With a dual-drive approach involving a German design team and a Chinese supply chain, the company focuses on meeting the commuting needs of European and American customers.

Testing Process

F-WHEEL Factory’s Product Testing Center boasts a comprehensive testing process, ensuring that every stage is rigorous and meticulous:requirement Analysis,test plan development,test case design,test execution,defect tracking and management,test report compilation.

Testing Capabilities

F-WHEEL Factory’s Product Testing Center possesses a wide range of testing capabilities and expertise:

- Functional Testing: Thoroughly verifying whether the product’s various functions meet the design requirements.

- Performance Testing: Evaluating the product’s performance under various usage conditions to ensure stability and efficiency.

- Safety Testing: Strictly testing the product’s safety to prevent potential risks and ensure user safety.

- Compatibility Testing: Ensuring the product’s compatibility in different environments and devices to enhance user experience.

Importance and Advantages

The Product Testing Center plays a critical role in the development of F-WHEEL Factory. Through scientific and systematic testing processes, the center not only enhances product quality and increases customer satisfaction but also provides a solid foundation for the company’s technological innovation. The center’s professionalism and advancement allow F-WHEEL Factory to maintain a leading position in the fierce market competition, earning the trust and support of a wide range of customers.

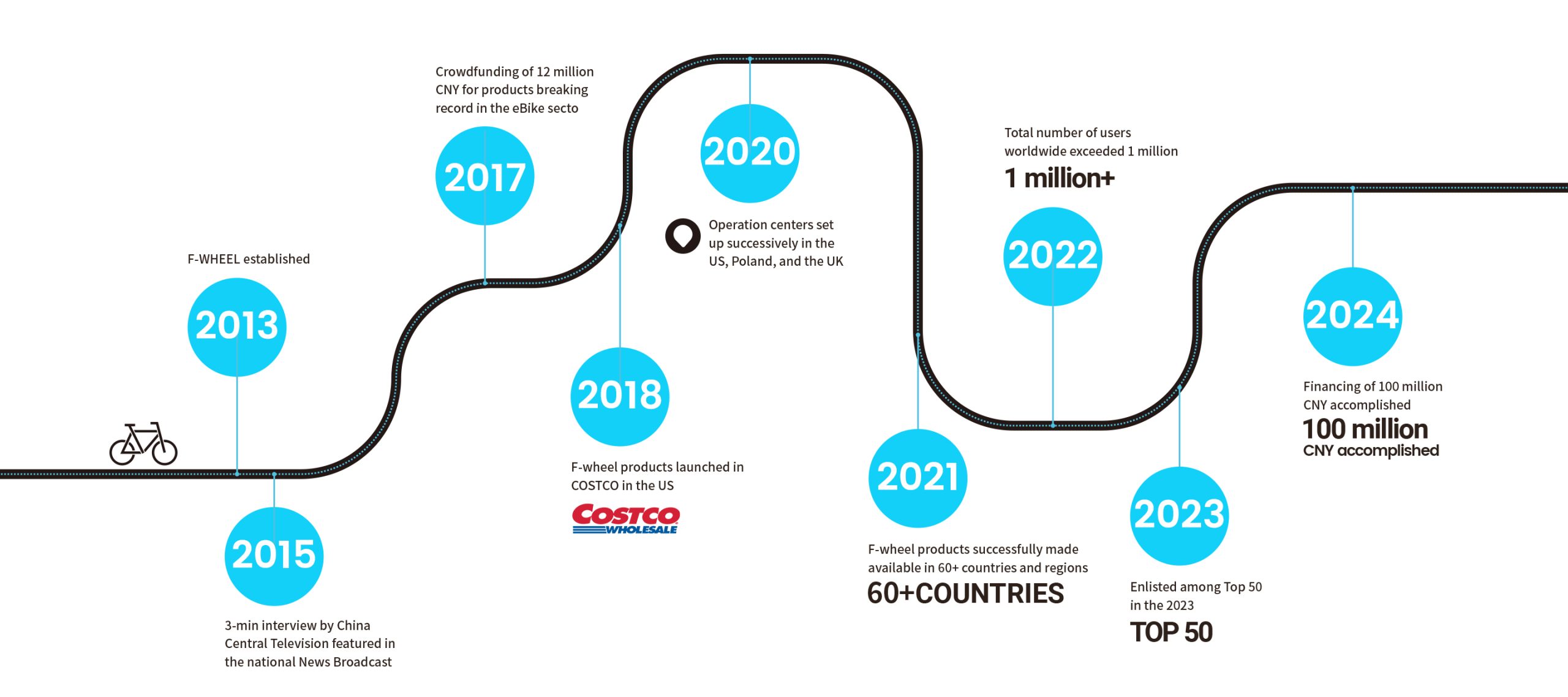

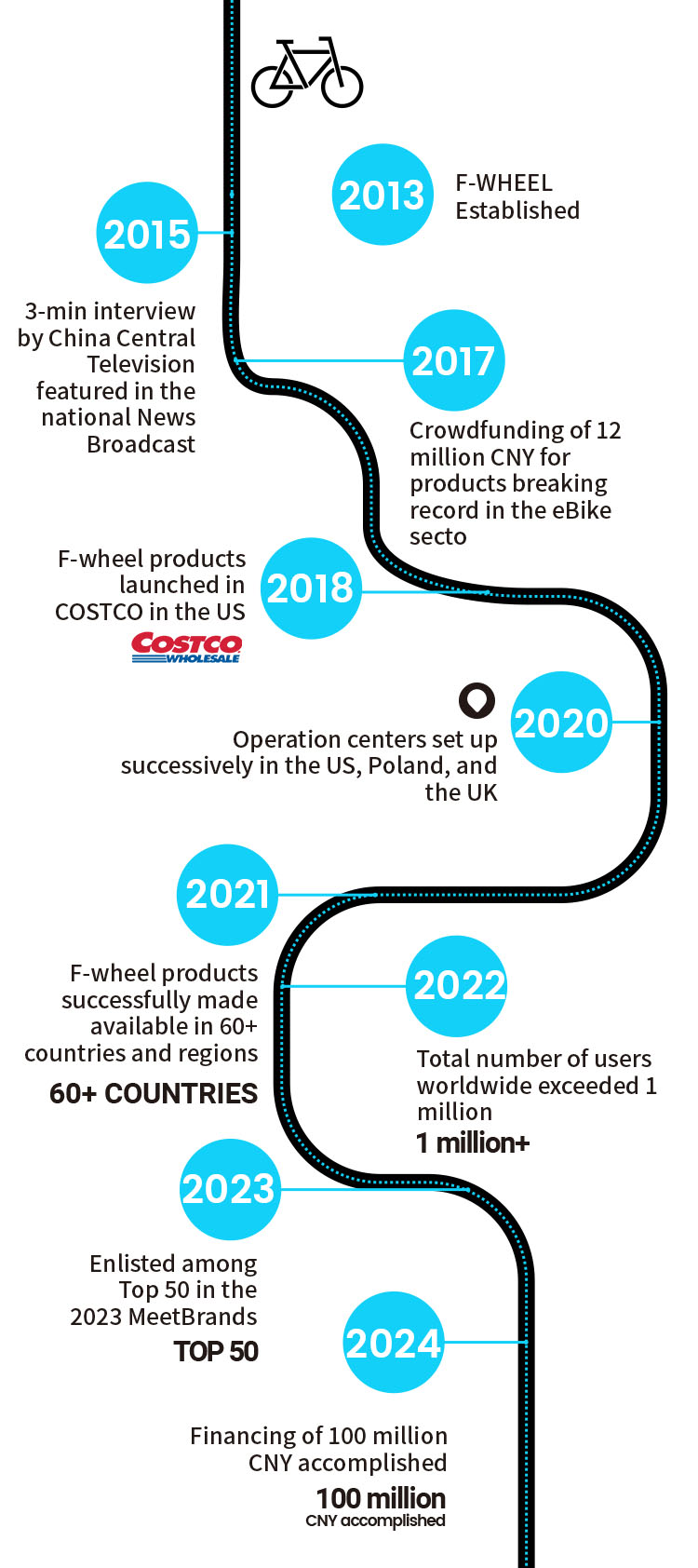

Campany milestones

F-WHEEL established

F-WHEEL establishedThe first product Q3 (now upgraded) independently developed and produced has been officially launched.

3-min interview by China Central Television featured in thenational News Broadcast

3-min interview by China Central Television featured in thenational News BroadcastFWHEEL held a new product launch event for Mini I Cloud Bike in Zhengzhou,China

Crowdfunding of 1.2 million CNY for products breaking record in the eBike sector

Crowdfunding of 1.2 million CNY for products breaking record in the eBike sectorFHWEEL Hosts Its First Online Launch Event to Introduce the D1, the First Foldable mini eBike with Tracking.

FWHEEL products launched in COSTCO in the US

FWHEEL products launched in COSTCO in the USLi Wei of FHWEEL Named to Forbes China’s 30 Under 30 Elite List in 2018, Becoming the Sole Representative in Smart Personal Mobility.

Operation centers set up successively in the US, Poland, and the UK

Operation centers set up successively in the US, Poland, and the UKHonored as One of the Top 10 Lithium Electric Vehicle Brands of 2020, CEO Li Wei Delivered the Keynote Speech.New Models S2 and L1 Launched.

FWHEEL products successfully made available in 60+ countries and regions

FWHEEL products successfully made available in 60+ countries and regionsLaunched the New R1, Sparking a Trend for Light Sport Mobility in Europe and America.

Named One of the 11 Coolest Must-Have New Products of 2021 by American Tech Media.

Total number of users worldwide exceeding 1 million

Total number of users worldwide exceeding 1 millionLaunched the new FF500, KING750, T1, and V8 models, which have been highly acclaimed.

Enlisted among Top 50 in the 2023 MeetBrands

Enlisted among Top 50 in the 2023 MeetBrandsLaunched the new c7 ,c9 models, which have been highly acclaimed.

Financing of 100 million CNY accomplished

Financing of 100 million CNY accomplishedWith the funds raised in this round of financing, F-WHEEL will establish a financial advantage, and the E-bike market landscape may gradually become clearer over the next two years.